Challenges and opportunities for particle control in advanced semiconductor manufacturing

Date Published: 2017 | Technical journal archive

Log in or Join UltraFacility to access this content

To access our resources you will need to be a member of UltraFacility, log in to your account or purchase a membership to view this content.

Already have an account? Log in

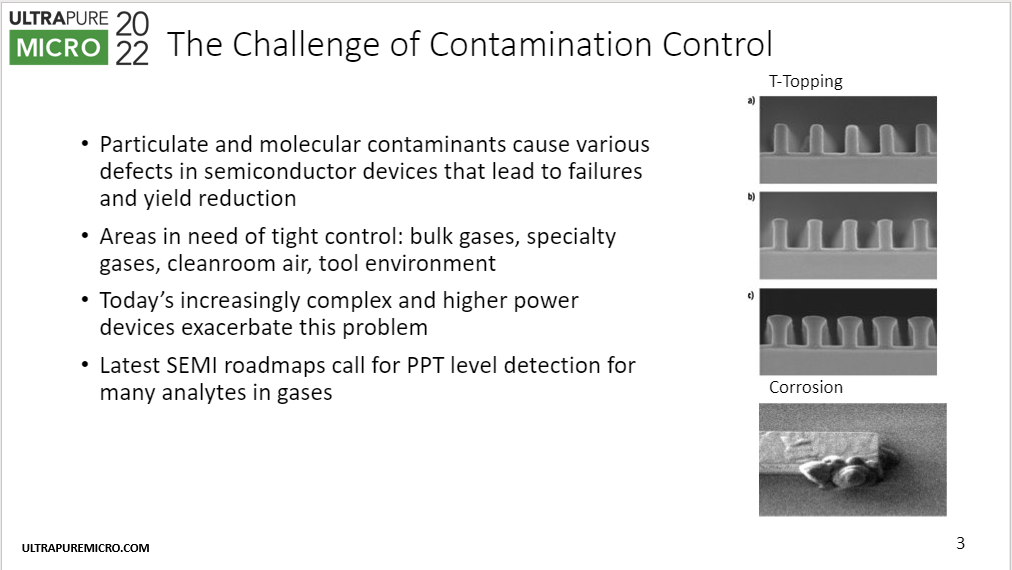

This article provides an overview of the biggest challenge of UPW technology – particle control. The latest semiconductor technologies require near particle-free water, where the “killer” particle size is far below the size that UPW metrology can effectively detect. Also, current advanced treatment methods cannot guarantee reliable removal of killer-sized particles. The quality of the high-purity materials used downstream of the final filters has not typically been tested for shedding of the “killer” particles. Consequently, the semiconductor industry requires a comprehensive approach for the particle control. A new approach should include mitigating particle occurrence and continuously improving the technologies used in UPW polish and distribution systems. Such an approach should also include extensive use of SEMI standards to improve the quality of the materials used; a new way to engineer solutions related to system-configuration and system design; improved process control; and a careful review of critical operational decisions. Collaboration throughout the industry via IRDS and SEMI Standards is key to enabling such systematic improvement, and overcoming the metrology and other constraints. This article was originally published in the Ultrapure Micro Journal in November 2017.