Chemicals under regulatory scrutiny: semiconductor industry

Share this insight

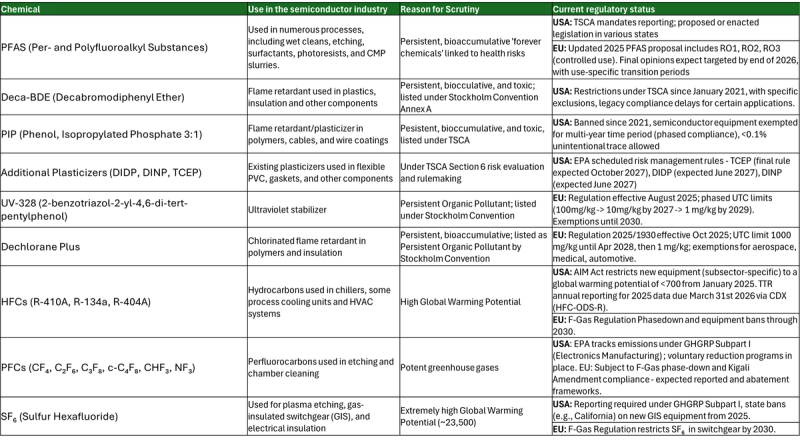

The table highlights a selection of chemicals and gases currently under regulatory scrutiny that are particularly relevant to semiconductor facilities. These substances affect a wide range of facility tools and subsystems, including HVAC and cooling infrastructure, electrical equipment, process gas handling, and the materials used in tools and components. Though non-exhaustive, the inventory focuses on regulatory pressures which are likely to influences facilities design, equipment selection and long-term planning.

Regulatory impacts take multiple forms. In some cases, requirements are limited to expanded reporting and record-keeping, such as under US TSCA or greenhouse-gas reporting programs. In others, regulations restrict the use of specific substances in new equipment, driving changes in refrigerants, switchgear, or materials of construction. Even where outright bans are not imminent, long qualification timelines for alternative chemistries and materials can introduce friction into facility upgrades, tool installations, and expansion projects.

Semiconductor facilities are typically planned and operated on 10–15-year cycles, meaning that both near-term and longer-term regulatory developments are relevant. In the near term, the most pressing issues for facilities teams include high-GWP refrigerants used in cooling systems, sulfur hexafluoride (SF₆) in electrical switchgear, and PFAS-related reporting obligations. These requirements are already influencing equipment specifications, reporting workflows, and compliance strategies across multiple regions.

At the same time, regulatory attention has focused heavily on PFAS mitigation in water and air emissions, reflecting broader societal concern around persistent “forever chemicals.” While this focus is warranted, it is only part of the picture. Parallel challenges are emerging around other substances, including high-GWP refrigerants and additives used in plastics, cables, and insulation materials. These chemicals may not be central to process recipes, but they are integral to the infrastructure that enables reliable fab operation.