Research update on particle precursor detection

Share this insight

Gary Van Schooneveld is President of CT Associates, Inc., and has over 30 years of experience with high-purity fluid systems, including chemical delivery and ultrapure water (UPW).

Gary provided an interview to update Ultrafacility on the latest research and development in addressing challenges in measuring particle precursors, the dissolved materials found in fluids which pose a threat to wafers when dried by forming a particle.

How do the particle precursors form in the manufacturing process?

When fabs rinse a wafer with UPW or Isopropyl alcohol (IPA) in a spin coating process, droplets will form on the micro scale in localized areas. If particle precursors are present, then when it fully dries out what will be left is the particle.

The other way particle precursors can form is interaction between materials. For example, during an UPW and IPA mixing process, each liquid may have particle precursors attracted to one another through chemical bonding or electrostatic attraction. Consequently, the particle precursors could come together and form a particle.

What are the current capabilities for detecting particle precursors?

Particle precursor metrology is primarily nebulization followed by a condensation particle counter. The technology can measure particle precursor concentrations in the parts per trillion level, which near-eliminates the risk factor of particle formation. Once you get below a certain particle precursor concentration, the formed particle is smaller than the critical particle size and therefore it isn't a risk. The metrology on the market for particle precursor detection is close to being able to provide that level of resolution.

So where is the limitation?

The current limitation is not in the instruments, but that the liquid systems don't have the capability of removing particle precursors below the detection limit of the of the instrument. Every time a water system improves, and better-quality water is produced, that particle precursor detection level reduces with it.

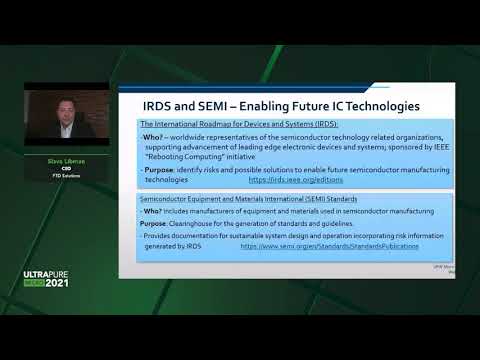

How is the industry, including SEMI and IRDS, responding to the particle precursor challenge? What are the most recent activities of these groups?

The IRDS UPW team is really the driver, establishing a specification around five years ago for particle precursors. The teams continue to monitor but have not changed the specifications since, because there doesn’t appear to be a need just yet. The team is currently working on converting the number concentration that was developed five years ago into a mass concentration. Since the particle precursor concentration is based on mass rather than numbers, this provides greater standardization between instruments.

Two years ago, SEMI developed a specification called SEMI F 121, which is a guide for establishing a standardized way to qualify a particle precursor measurement tool. Based off experimental work, the specification provides a common way for particle precursor metrology manufacturers to calibrate and validate performance.

Can the industry can assist in collaborating on the research?

Yes, there's support that the industry can give. A lot of these experiments are being done within the IRDS or SEMI, but these organisations don't have funding, so research is supported by companies who are part of the team or have an interest in improving their materials.

More industry participation in both IRDS and SEMI in the chemical or UPW critical components area will help move efforts along. Suppliers who have an interest in improving their materials can provide either financial resources or supply some of their materials for part of the study.

How can fabs practically reduce the risk posed by particle precursors in UPW?

Take advantage of the metrology that is available now. There are at least two manufacturers that make these types of instruments, which can show how their systems are performing and monitor input water. Fabs can help direct research too. If they see something that they don't understand, but suspect particle precursors, they can engage with IRDS and SEMI to get input from experts and inform industry progress.

How will the particle precursor challenge evolve as sensitivity increases?

Work will be done to understand the link between defectivity and particle formation, to determinate the rate of on-wafer particle formation from a certain concentration of particle precursors in a liquid. As we understand this correlation, we can better define the risk level, then help the industry understand particle precursors levels to reduce wafer defects.

The IRDS UPW team just finished a study which analyzes this correlation with UPW and IPA, measuring the particles formed on the wafer. We are using the UNISERS instrument which allows visibility down to around 8 nanometres. We must continue that effort for other chemicals and other sources of particle precursors.

The IRDS critical components team is preparing an experiment to determine the level of particles which will form on a wafer using PFA and PVDF piping and tubing that has been extracted with UPW.

In addition to this research, are there any technology gaps which must addressed in the next three to five years?

The challenge is utilizing this type of particle precursor instrumentation on other chemicals. For UPW it is straightforward to utilize these methodologies. IPA is relatively straightforward, other than dealing with the flammability aspect. However other chemicals, such as acids, bases, photoresists, other solvents, have different challenges in the nebulization method and solvent removal. Significant challenges must be addressed to move forward into other chemicals.

Why has less progress been made in chemicals?

The last contact on the wafer before the drying process is typically UPW or IPA, making these two liquids the priority for research. These other chemicals are a concern, but typically you have a rinse process to reduce the risk.

However, sulfuric acid raises significant concern because it will leave a residue, and if that residue is non-volatile, it can result in a particle. So, it’s not that there isn’t concern, it’s just the industry is dealing with the last rinse first.

See the Ultrafacility technical knowledge base for more insights on metrology and particle precursors, including Application of a New SEMI F121 Guide for Evaluating Particle Precursor Metrology | UltraFacility

Share this insight

Collaborators

Gary van Schooneveld

President

CT Associates Inc