Tech talk: AI for Wastewater Enters Its Next Phase of Practical Application

Share this insight

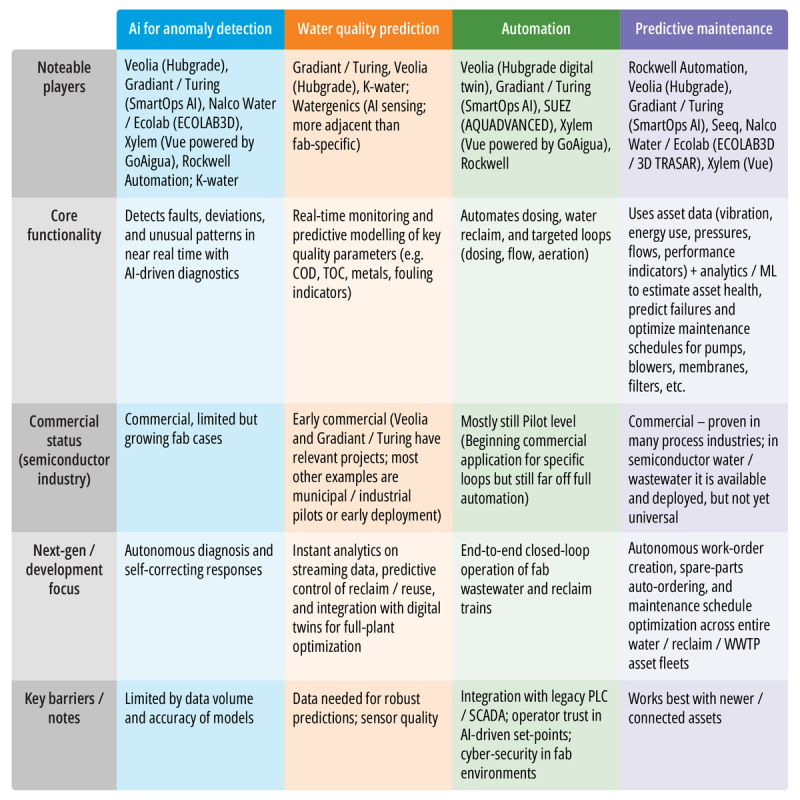

Momentum is accelerating for AI adoption in wastewater treatment. While facilities have historically lagged behind other areas of the fab in AI and digitization, broader commercial use is expected within the next one to three years. Recent infrastructure upgrades have improved monitoring networks and data reliability, creating the foundation for effective AI deployment. Early applications focus on predictive operations and process optimization, helping operators respond to highly variable influent conditions while reducing chemical consumption, energy use, and unplanned downtime. As capabilities mature, AI integration with digital twins is enabling near-real-time simulation of system performance and identification of discrepancies between expected and actual behavior. This is laying the foundation for increasing autonomous control.

The main barriers to adoption stem less from technical constraints and more from organizational hesitance: facilities must modernize legacy systems, ensure secure data sharing, and build confidence in AI-driven decision-making. Ultimately, system providers’ ability to demonstrate clear value and superior reliability over current practices will determine the pace of industry-wide uptake.

Current applications focus on moving from reactive to predictive operations

The first stage in AI adoption is allowing facilities to better utilize data. By improving how facilities use their system data, AI helps operators anticipate issues rather than react to them. As Mike Boyd, Water tech domain lead at Veolia explained, the current implementation of AI for semiconductor wastewater is at a foundational level, “AI is supporting operational tasks; such as performance optimization, live waste tracking, automated chemical procurement and predictive modeling for equipment maintenance. This insight allows operators to proactively plan for downtime.” Veolia has developed models to optimize unit operations such as membrane systems and segregated waste stream flow sheets.

Commercially available solutions are advancing beyond condition monitoring, using AI to provide recommendations based on asset health. “Condition monitoring means an asset can tell you it's health right now, but if it can tell you, based on that data, what will go wrong in six months or a year, that is predictive.” explained Dinesh Saigal, technical program director at Applied Materials.

Additionally, companies such as Gradiant are already using smart sensors for water quality prediction. They can estimate key water quality parameters from a minimal set of sensor data, providing clarity on water quality without the cost of monitoring every contaminant. This is expected to become more widely adopted, as AI can instantly analyze large quantities of raw data.

Taking AI further with digital twins

Heather Tugaoen, General Manager, North America of Watergenics, noted that wastewater remains “one of the downstream efforts where there's a lot of room for opportunity,” reflecting the fact that sensing, automation, and analytics are still less mature than in ultrapure water or process tools.

The focus until now has largely been on building out and cleaning data so it can be better leveraged by AI models. AI is now being integrated to strengthen data-driven models and expand their predictive capability, which can in turn be integrated into tools like digital twins. AI compares expected system behavior in the digital twin with real measurements to highlight anomalies and faults and suggest adjustments accordingly. Digital twins thus serve as both diagnostic tools and decision-support systems.

Digital twins offerings are expected to advance significantly in the next couple of years. Turing CEO Hiep Le highlighted that most digital-twin deployments today are still data-driven rather than physics-based. Turing is using AI to integrate domain knowledge on treatment process behavior into digital twins, enabling true simulation rather than pattern matching.

Automation can ease workforce pressures, but AI reliability must be proven

The industry is expected to shift toward greater automation over the coming years, especially for repetitive, time-sensitive tasks such as chemical-dosing optimization, membrane fouling control, and optimizing reuse. “Whenever there's human intervention, there's going to be a lag, and once you implement AI, you can close that loop a lot faster and there is better responsivity to different input parameters,” explained Tugaoen. She noted that AI can also enhance internal water reuse by continuously monitoring reclaimed water quality and identifying where it can be reintegrated based on purity requirements. Ryan Kovalchick, engineering & automation manager at Intel, said that AI is already capable of sophisticated decision-making when supplied with clean, comprehensive datasets. He expects that within five years, robotics paired with AI will be capable of performing substantial portions of maintenance and even core operations tasks. “Looking ahead, I believe we're on the cusp of a major shift where AI-powered robotics will handle not just routine maintenance tasks, but increasingly complex operational functions. Within the next five years, I expect to see these systems taking on substantial portions of what we traditionally consider core operations work.”

However, achieving closed-loop operations where AI autonomously responds and adjusts in real time will require not only technological readiness but also a cultural shift. A source emphasized that robustness and safety must be demonstrated before generative AI can operate inside facilities: “It can help with the monitoring of the assets, reliability, predictive maintenance, but the first thing we need to do is to create confidence that this new solution is at least as reliable as the practice they have now.” He anticipates early testing of generative AI copilots within the next two to three years.

IP constraints will limit AI adoption until proven gains outweigh security concerns

In addition to proving AI capabilities to increase trust, another barrier to AI adoption is the industry’s hesitancy to share data. According to Boyd, this can be a greater constraint than technological limitations. “There's no reason we can’t model the entire plant, from UPW to end of pipe. It’s very feasible, the first challenge is having all the data, the second is getting all the data, which leads to lengthy data security and IP discussions. ”This reflects a key industry challenge: wastewater analytics depend on cross-facility data integration, yet semiconductor fabs impose some of the strictest data-security rules of any industrial sector.

An AI systems provider described how they address this concern by running systems on the edge, meaning the models operate on local devices within the treatment system instead of relying on the cloud, so customer data doesn’t leave the facility. Veolia reported similar experiences, relying on manual transfers or firewall-protected exchanges to maintain confidentiality, while Turing mitigates cloud risks through on-premise AI deployment. While these approaches maximize data protection, they inherently limit model retraining, fleet-level benchmarking, and cross-facility learning, which are central advantages of modern AI.

Progress will depend on greater willingness to share data securely. “At some point, the opportunities will force us to figure out a solution. We are missing out on too much,” said Tugaoen. Boyd agreed, adding, “We’ll get to a tipping point, where the efficiency gains recognized by utilizing deep learning models will be undeniable. This will turn the table from being a vendor promoted solution to an end-user required service.” Hiep Le added that the industry is cautiously beginning to accept controlled cloud use. “It’s happening soon, and the simpler path to cybersecurity may be through private cloud deployment.”

In the near term, data control will continue to slow AI integration, but as digital technologies become central to fab operations, addressing security and trust barriers will become a shared industry priority.

Significant potential to retrofit systems for existing sites

There is demand for both off-the-shelf AI solutions and tools that can be retrofitted into existing systems. As Le noted, “AI is easier with new systems because it becomes part of the design, but there is still plenty of opportunity in the existing systems to integrate.” For semiconductor facilities in particular, retrofit approaches offer a practical starting point. A source explained to Ultrafacility, “In the US, every single new facility is tens of billions of dollars investment in multiple years. Therefore, the first line of defense for any company is to optimize their existing utilization of assets. I believe that would be the perfect entry point for AI solutions.”

Because fab utility systems typically operate for 20–30 years, there is a significant incentive to improve performance without replacing major infrastructure. Tugaoen noted, “There's always room to retrofit, I think it's just a question of what additional sensing and technology is required to be able to get the information you need to be able to do that.” In practice, this often involves adding or modernizing flow, pressure, conductivity, Total Organic Carbon (TOC), or vibration sensors.

Agentic AI is making tools more accessible for semiconductor applications

System providers face significant challenges tailoring solutions to highly variable semiconductor wastewater operations, including numbers of segregated waste streams. Emerging agentic AI approaches are beginning to reduce this customization burden by enabling systems to adapt and learn from each facility’s operational data rather than relying solely on pre-engineered models. In the long term, adaptive architectures may become the standard approach, though progress will depend on overcoming persistent data-sharing and access constraints.

Agentic AI is transforming the operator's experience. An AI system provider explained tp Ultrafacility that operators no longer need deep familiarity with data-driven models to benefit from them, “the control system remains as it was, so the operator saw no difference. But there was an intelligent AI engine in the back end recommending small changes to improve performance.” This eases the integration of AI into decision making and minimizes additional training operators require to operate new systems.

These intuitive systems are valuable training tools to address the industry’s skills gap. Le noted, “We think of AI like an assistant to the operations team, giving them superpowers with an intuitive user interface, displaying the relevant data and AI insights in a way that explains why the AI is giving that recommendation.”

Measuring Return on Investment

While AI offers a broad range of operational benefits, providers are prioritizing applications where performance gains can be clearly quantified. Kovalchick highlighted the challenge in quantifying the value of AI; “the big problem I am seeing with the adoption of AI is being able to prove the business value, especially because there are things you don’t even know it can do yet.” This is a key challenge for systems providers, prompting providers to target easily measurable improvements like energy as they provide a solid basis to calculate the return on investment.

Saigal highlighted that focusing on critical utility assets yields strong early returns: “Go after the rotating machinery, there is a lot of good low-hanging parameters, vibration, RPM, current, pressure, and there may be thousands of machines, so it is a huge business case if you can fix them before they cause an issue.” Even minor optimizations, scaled across numerous assets, make AI’s value compelling. Le seconded this, adding “Target the type of wastewater treatment that has reliability challenges and positive cost optimization opportunities, chemically intensive processes like HFW.”