Tackling the PVDF supply chain bottlenecks

Share this insight

Over the past three years, the semiconductor industry has faced a critical materials shortage, high demand for microchips, and supply chain bottlenecks. Even as the impact of COVID-19 begins to fade and demand for microchips softens, bottlenecks persist for basic construction materials such as concrete, steel, and fluoropolymers. The shortage of fluoropolymers is expected to last into 2024, and their use in the semiconductor industry is crucial due to their chemically inert and temperature-resistant qualities. Polyvinylidene fluoride (PVDF) and perfluoroalkoxy (PFA) are among such critical materials and are necessary for transporting high-purity liquids and ultrapure water (UPW) with minimal extraction of impurities into the fluid.

Since early 2022, the availability of resins to manufacture PVDF piping has come under severe pressure, as the growing electric vehicle industry competes to use the material for thermal insulators in batteries. John Painter, Principal at Pure Facilities Solutions, told UPM: ‘A major problem in the semiconductor industry is caused by supply chain issues occurring in the midst of a construction boom. For ultrapure water, the PVDF piping shortage represents a key bottleneck. There is a major shortage of PVDF resin and there are only a handful of major companies globally that produce resin of sufficient purity. The microelectronics industry is also in competition for this vital material with other markets, such as the electric vehicle and lithium battery industries. These related markets do not need PVDF resin with the same high quality as the microelectronics industry and are purchasing large quantities, thus driving up prices. As the market adjusts, this limits the production and output capabilities of high purity water piping suppliers for the microelectronics industry.’

While competing for critical materials with other industries, how can the semiconductor industry adapt to ensure continued operations and minimize costs? There is an emerging opportunity for manufacturers and solutions providers to collaborate and address these supply chain issues while adopting environmentally sustainable practices and ensuring consistent purity.

One such example of mitigating PVDF shortages is investigated in a UPM 2022 technical paper entitled 'Re-usability of PVDF UPW piping'. Christian Schiefer, Georg Fischer Piping Systems, explained that through proper risk mitigation in removing PVDF piping at its end-of-life, it is possible to reuse PVDF piping in other UPW applications. Emerging data suggests semiconductor manufacturers could avoid compromising purity when reusing the pipe, and thus have a big impact on contributing to the circular economy, reducing costs and minimizing the strain on the supply chain.

Schiefer also explain that current established methods allow PVDF to be reground and repurposed for less high-purity application, but the market for this is currently relatively small. However, it is also currently important to undertake optical and mechanical testing to assess the condition and aging of the PVDF. This inert and stable material may have a longer lifespan than originally planned, adding extra years without compromising system reliability or liquid purity.

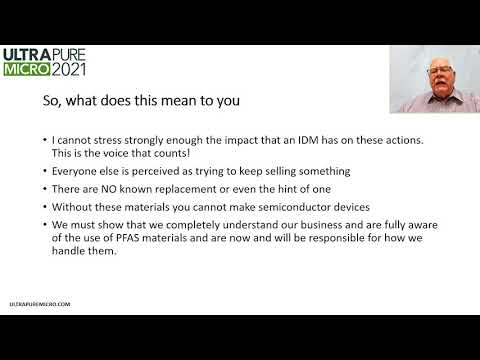

Exploring possibilities for PVDF usage is crucial not only for alleviating supply chain issues but also for mitigating the environmental impact of per- and polyfluoroalkyl substances (PFAS), which are the subject of potential forthcoming regulations in the US and the EU. By maximizing the PVDF usage period, the semiconductor industry can reduce the quantity of PFAS-containing materials sent to landfills.