DAS Environmental Expert

Headquarters

Dresden, Germany

Company size

251-1000 employees

Services

About

DAS Environmental Expert, founded in 1991 in Dresden, is an industrial waste gas and wastewater treatment systems integrator that offers a wide range of biological and chemical-physical technologies to reduce pollutants. DAS Environmental Experts works across a range of industries in the wastewater treatment space, and the semiconductor industry features as its most important customer.

The company specializes in point-of-use (POU) abatement technology, for waste gases and wastewater, developing processes specific to client needs. With a variety of waste gas abatement technologies such as wet scrubbers, electrostatic filters, rotary dust collectors and burn/wet and burn/dry technologies, DAS EE deals with the diverse range of process waste gases that are employed during semiconductor manufacturing.

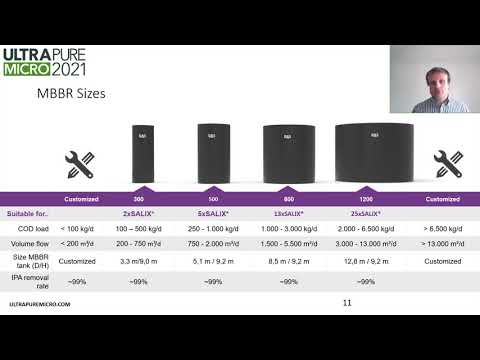

DAS also employs a broad spectrum of wastewater treatment processes, including Centralized, Semi-Centralized & POU Systems, depending on the customer's specific needs. Its services range from consulting (including laboratory and pilot tests) to planning, plant construction, commissioning, optimization and maintenance of wastewater treatment plants. The company analyses wastewater in the laboratory to determine composition and biodegradability, creating a treatment solution based on the individual results.

Innovation

DAS also focuses on innovation to increase efficiency and reduce the environmental impact of semiconductor activities, including developing procedures that will allow for resource recovery of rare elements from wastewater, working towards a circular economy model. It has also developed a solution for secondary purification for NOx-generating exhaust gas cleaning systems, such as burn-wet systems, working with minimal energy consumption by recovering over 75% of process heat.