Tech Talk: The Market Reality for UPW Particle Counters

Share this insight

A slowly evolving landscape

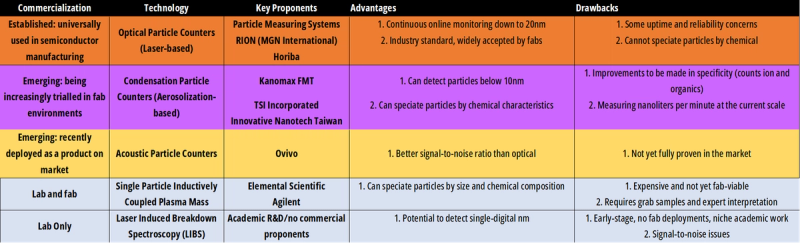

The International Roadmap for Devices and Systems (IRDS) identifies ~3.5 nm as the “killer particle size” for UPW, large enough to cause a defect on the wafer. Yet the physics of optical particle counting (OPC) – the traditional workhorse of UPW quality monitoring – limit detection to ~20 nm. Some advanced fabs run 20 nm counters and specifications today, whereas many are even limited to 50nm specifications – despite wanting to go lower – due to instrument reliability limitations.

The technology landscape for UPW particle counters is fairly static. As such, the short-term addressable market opportunity for instrument suppliers lies in new fab buildouts or replacement cycles, with good particle counters staying in place for 10-15 years. Filter manufacturers are also consistent customers for this instrumentation for quality testing.

However, the bottleneck for technology innovation is not about physics alone – it is economics and risk. Insufficient capitalization on reliability improvements, excursion diagnostics, and investment in breakthrough technologies means there is a hard-to-crack but potentially revolutionary opportunity vacant for industry newcomers.

Reliability vs. sensitivity - the customer's dilemma

Despite the industry’s trajectory towards smaller critical dimensions, with advanced node manufacturers asking for sub-10nm monitoring, the emphasis on reliability and confidence in data is the greatest customer ask of all.

Jochen Ruth, SLS director – microelectronics Europe at Pall said: “The industry is conservative for a reason. A new technology has to prove not just that it detects more, but that what it detects is meaningful for its impact on production.” He added that the more sensitive a counter is, the more costly it can become, as maintenance costs increase, and calibration gets more difficult.

This known phenomenon – that more sensitive particle counters produce more noise – is a core market barrier to investment and development, with only a few players pushing the boundaries.

“Measurement sensitivity is important, but stability is also important,” added Najib Alia, Head of Innovation Nanotechnologies at Ovivo. “Customers want data that is reliable, without interference from bubbles, vibrations, or external factors, as it takes effort for the engineer to distinguish a real excursion.” To combat signal-to-noise challenges, Ovivo is one of the only companies to develop acoustic particle counting as an improvement (though other companies have trialled developing this technology). Ovivo’s acoustic technology entered the market 2 years ago.

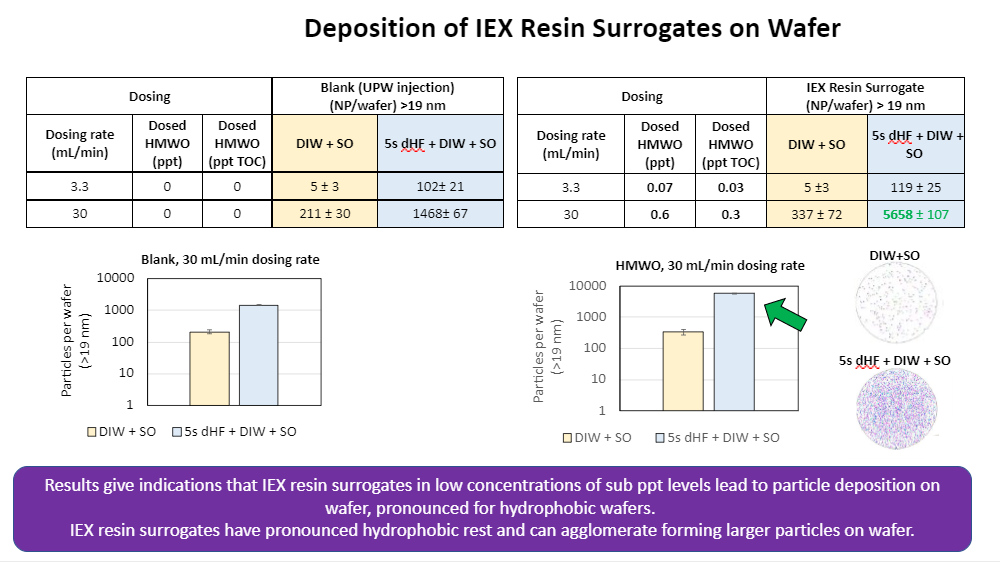

Emerging technologies include aerosolization-based condensation particle counting, which has the proven capability to detect particles below 10nm but picks up non-particulate contamination such as ions and organics. It has made headways into the semiconductor industry but is not utilized on a widespread basis in the same way as OPCs as its use case is more suited to extremely advanced nodes or for profiling excursions.

The role of UPW particle counters vs other metrology

The role and importance of UPW particle counters is changing. Derek Oberreit, vice president at Kanomax FMT told UltraFacility: “There’s been more focus on IPA than UPW for metrology – a lot of that is driven by the need to reduce wafer pattern collapse. Generally, UPW systems are stable, and it takes a big excursion or major mistake for water quality to degrade to the point where it leads to wafer defects. So, the demand for UPW monitoring hasn’t been as strong as it once was, but it is not going away completely.”

Oberreit explained the transition of the particle counter’s role: “I don’t see particle counters going away, but they will be part of a toolkit – system profiling, chemical analysis, and excursion monitoring. They have always been used alongside other metrologies like Total Organic Carbon Monitors and offline ICP-MS.” He added: “Customers don’t just want particle counts — they want system fingerprints – i.e., mitigating the potential for excursions or general loss of UPW quality by fingerprinting consumables such as filters, ion exchange resins, and critical components..” This will become increasingly important at advanced nodes where new materials and components, such as valves and pumps, can shed particles at ultra-low thresholds. Oberreit recommends measuring as close to the dispense nozzle as possible for tools with critical rinsing steps, as many defects trace back to a single problematic tool.

Gary Van Schooneveld, President at CT Associates sums it up well: "Online particle counting by OPC has always been a key tool for measuring particle concentration in UPW and other chemicals. The issue is not a lack of interest in particle concentration but the inability of OPC to measure the particles to the sizes that impact yield. Online particle metrology capable of measuring to the critical size of 2 to 3 nm is very important but requires fundamentally different technology to measure at this size. Facility engineers still need a go, no-go measurement for particles and additional analytical tools that can be deployed when no-good situation exists." He added that proactive particle management is also needed where measurement of particles is very difficult due to access to sampling. This is why qualification documents like SEMI F104 are key to mitigating particle shedding concerns post filtration or sampling location.

Risk and cost affects the role of the particle counter

Ruth explained that if a fab follows the IRDS’ proactive contamination control philosophy – designing, building, and operating in accordance with SEMI F61 – the final counter should not detect contamination. As such, monitoring upstream of the final filters is more valuable to provide diagnostic control and identify excursions. “Particle counters were once used to correlate directly with wafer cleanliness, but that has changed,” Ruth said. “No particle counter can go to the truly critical sizes today, so their role has shifted to monitoring system performance rather than final water quality.”

However, the market reality also lies with the perspective of the end-user, revealing the continued importance of particle counters and the economic barrier to excursion diagnostics. A Principal Engineer at a leading semiconductor manufacturer told UltraFacility that “at our sites, we typically only have one counter, and it’s downstream of the final filter. That’s the point where the water is heading to the fab floor, so if we see something there, we know it matters.”

“Due to the price , these counters are intended to be installed at crucial locations only,” added another engineer from the same semiconductor company. “If someday the particle counter could be as cheap as turbidity meters, then facilities could install the counters across the whole UPW system.” Very advanced particle counters can have a price tag of up to $250,000, which explains the need to be conservative in usage.

Market shake-up opportunities

Until a technology can deliver proven stability, the bulk of the market will remain anchored to 20 nm OPC instruments, with incremental upgrades valued more than radical leaps. Mike Naggar, President at MGN International explained that “OPCs remain the baseline because all historical SPC charts and PORs are built on this data, so new methods must correlate back to historical results to be accepted.”

However, there are opportunities for tools which might be able to help end-users make decisions based off these historical results. A senior contamination control engineer from a major semiconductor company mentioned that a key barrier to the adoption of sub-20nm LPCs is “a lack of management tools like data transmittal tools, and a lack of historical baselines. As such, it is difficult to get particle standards, do controlled testing, and verify vendor claims.” Overcoming this barrier will be instrumental to implementing new technologies in the market. The end-user added: “It would be good for the vendor community to come together and provide some standardized data, instead of everybody showing different plots with different units. That would help us make a more informed decision.”

Furthermore, semiconductor facilities see the problem in relying on a narrow pool of vendors and would welcome diversification to encourage competition and investment in this demanding market. Increased market competition would spur short-term achievable outcomes which the semiconductor facilities are asking for, such as improved customer services through algorithms or user interfaces customized to the individual need. It is important that OEMs know 24/7 monitoring and seamless data exporting/transmission to customer systems is an absolute must for end-users, who need online monitoring. These are concrete aspects to address in the market.

Alia explained: “I don’t expect that there are any new disruptions coming to market, but the current technologies always have something to do better.” In addition to the customer needs above, some of the short-term success for developments in the market can be found in hybrid approaches. For example, Naggar added that RION is working to develop a hybrid optical particle counter with various options for signal boosting and noise reduction, to push sensitivity lower while keeping correlation validated to OPC data.

The end-user team stressed that the industry really does want more reliable and sensitive particle counters, and their importance is not going away. A breakthrough technology would surely be meeting a key industry need for some of the end-users who value the role of the particle counter in their contamination control methods.

Looking to the future: sustainability as a new driver

Despite the fairly static metrology landscape, new sustainability drivers bring new use cases for metrology. For example, Oberreit explained: “With the push to reduce chemical consumption, particle counters will be important for smarter end-pointing – i.e., deciding when filters are rinsed enough or when resins are exhausted, rather than just flushing/replacing based on fixed volumes.” In addition, as fabs begin to prioritize reclaim and recycle more – more fabs might be interested in monitoring contamination of reclaimed water.

Furthermore, traditional rinses are evolving, and metrology needs to adapt to those changes – hazardous chemicals such as TMAH are being gradually removed from the process, meaning more proprietary rinses will be used, and instrument providers will need to adapt their tools to detect unknown contaminants. Measurement tools will evolve alongside chemical changes and innovate to keep fabs confident.

A future UltraFacility tech talk will focus on the similar yet more rapidly evolving landscape for metrology for high purity chemicals.

The UltraFacility Technical Knowledge Base has a myriad of research on UPW particle counting - so please check it out for further details.

Share this insight