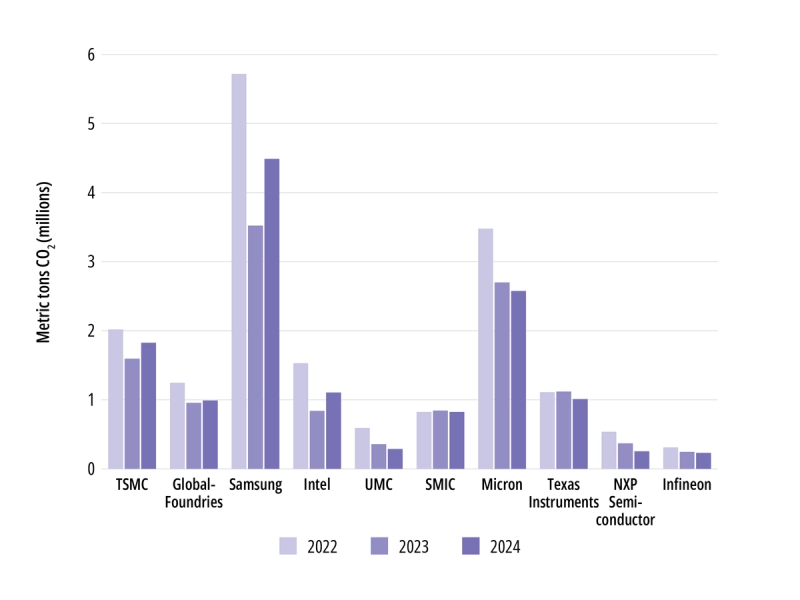

Semiconductor in numbers: Scope 1 emissions for ten leading chipmakers

Share this insight

This graph shows Scope 1 emissions for 10 major semiconductor manufacturers. Samsung was the highest emitter in 2024, followed by Micron and TSMC. NXP achieved the largest reduction from 2022 to 2024 at 52.7%, with UMC close behind at 51.4%. SMIC was the only manufacturer that did not reduce emissions during this period.

Samsungs emissions remain high despite installing advanced process gas treatment facilities like regenerative catalytic systems (RCS) and expanding waste heat recovery. The company relies heavily on LNG-fired boilers for heat, driving substantial emissions, and the majority of its manufacturing takes place in South Korea, where renewables remain scarce. Samsung cut Scope 1 emissions by 38% from 2022 to 2023 but saw a 28% increase in 2024, reflecting the struggle between production growth and its gradual decarbonization efforts. Moving forward, Samsung plans to expand its power purchase agreements (PPAs), focusing on regions with existing renewable energy supplies.

This pattern of rebounding emissions in 2024 is also seen from TSMC and Intel. TSMC’s emissions fell 20.9% from 2022 to 2023 but rose 14% in 2024, mainly due to production ramp-ups and new fab operations that increased on-site fuel and process emissions. Although non-Taiwan sites, including TSMC Arizona, have maintained net-zero Scope 1 emissions since 2022, most manufacturing in Taiwan still rely partly on carbon-based fuels, contributing to higher direct emissions.

Intel’s emission rebound likewise reflected increased fab activity. Avoided Scope 1 emissions, achieved through chemical substitution, abatement, and efficiency programs, declined from 10.3 million metric tons CO₂e in 2022 to 8.4 million in 2023, which would contribute to the rising emissions in 2024. As newer fabs and advanced processes, including 18A, moved toward high-volume production, total emissions rose despite continued mitigation efforts. Despite this, the companies' emissions remain low compared to others of a similar size and has achieved 98% renewable electricity use.

NXP Semiconductor saw the largest decrease in emissions from 2022 to 2024, at 52.7%, focusing its reduction strategy on upgrading tools and installing abatement equipment, purchasing renewable electricity, optimizing manufacturing processes, and substituting chemicals with lower global warming potential. Lowering perfluorocarbon (PFC) emissions has been a key focus, through the above measures NXP has lowered associated emissions by 67% since 2015. Importantly, unlike other manufacturers, NXP did not ramp up production during this period since its Dresden and Singapore fabs are still under construction, giving the company flexibility to achieve emission cuts. Maintaining these reductions will be challenging as the new fabs begin production around 2027.

Share this insight